Download PDF catalog

Read catalog online

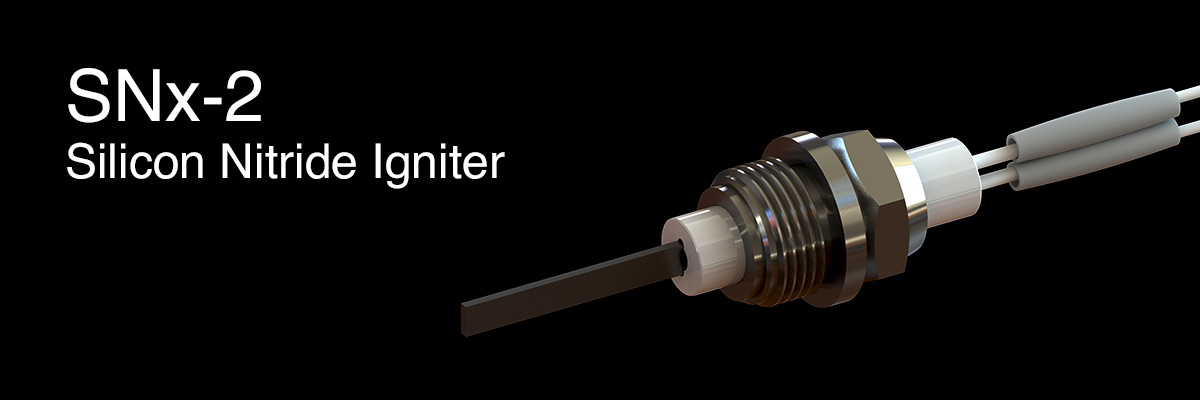

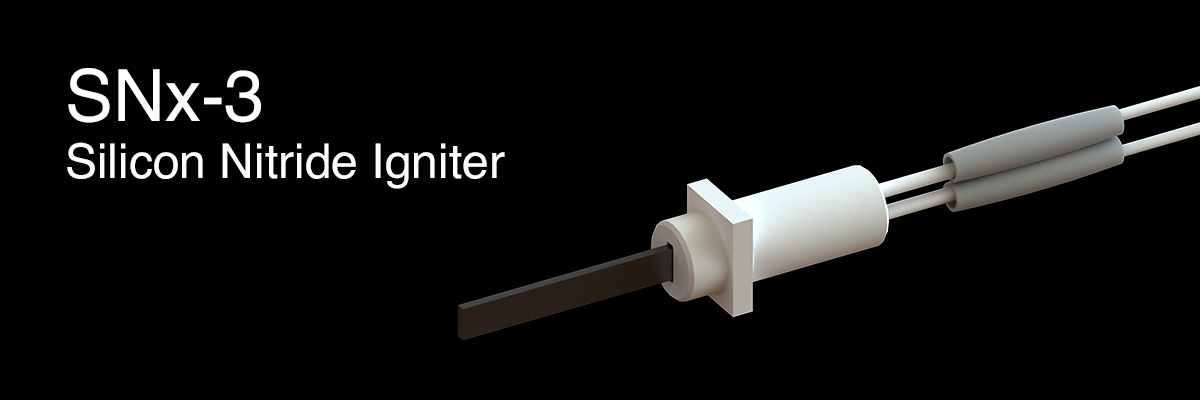

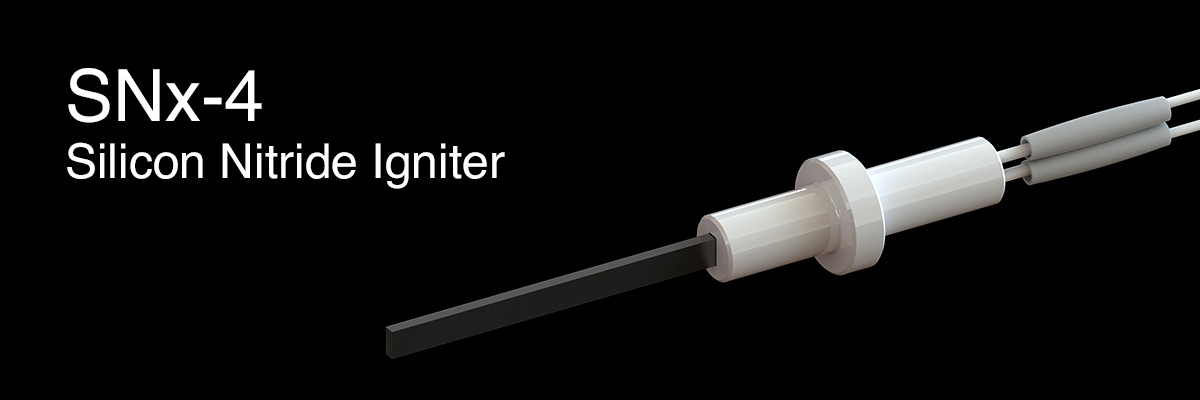

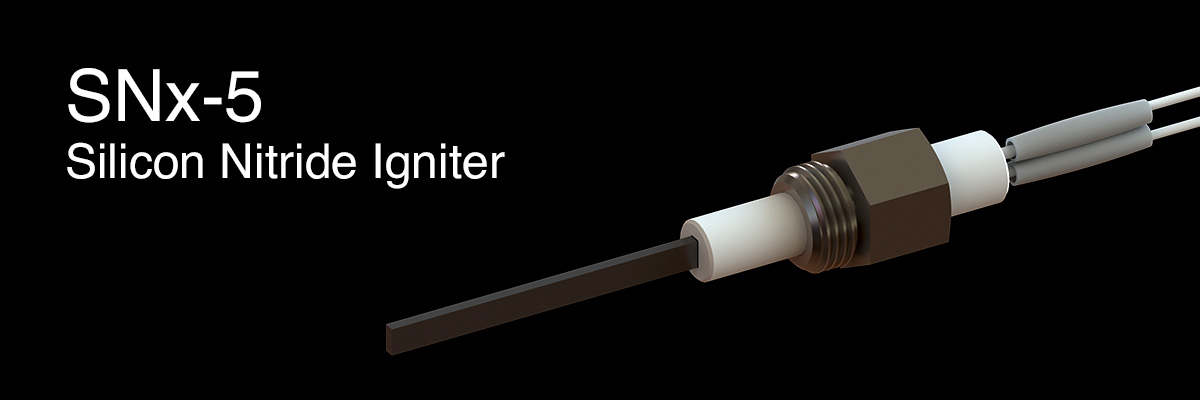

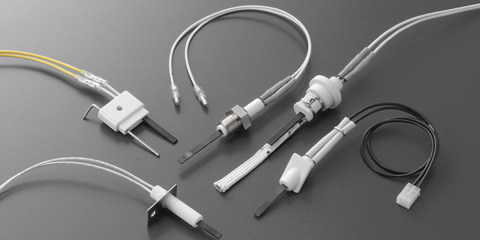

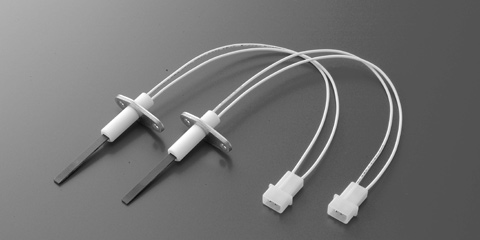

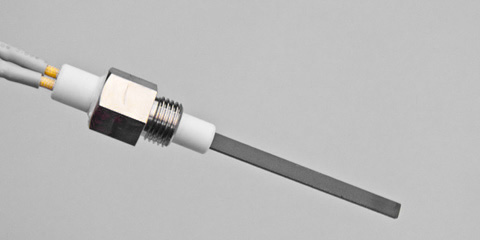

FKK Corporation producing OEM custom order ceramic silicon nitride igniters for gas and oil energy-efficient equipments.

FKKCorporation is now one of the world’s leading producers of ceramic igniters for compact boilers and tankless water heater as well as Fuel Cell SOFC/PEFC appliances, covering Asia and America .

Why choose FKK

- OEM Manufacturer since 1954

- Japanese quality

- Suggestion of new design

- Engineers team at your service

- Unique test equipment (x-ray, high temperature benchmark)

- Fast delivery

Fast and high temperature

Heating lenght is faster. up to 1000°c in 8 seconds. FKK ceramics igniters can reach 1450°. However, due to perfect sealing process, lead wire temperature do not exceed 150°C.

Applications

- Furnace, burner

- Gas, oil water heater, boiler

- SOFC, PEFC, Fuel Cell MCHP Burner components

- Other specific equipment

Long Rated life

While standards igniters only last 2 or 3 years, FKK ceramics igniters are made to last.

Features

Long Rated life

- While standards igniters only last 2 or 3 years, FKK ceramics igniters are made to last at least for long years (nearly 10 years possible) according to Japanese standard and made to be very resistant in all conditions (high humidity, freezing temperatures, strong vibrations, etc.). We are the unique maker in the world to be able to design SiN igniters with average life greater than 90,000 hours in continuous operation at 1300°.

High temprature, high constraint

- FKK ceramics igniters can reach 1450°. However, due to perfect sealing process, lead wire temperature do not exceed 150°.You can miniturize your system, make it safer and prolonge the rated life of other components.

Faster

- Heating lenght is faster. up to 1000°c in 8 seconds

High efficiency

- High-watt density discharge allow high thermak efficiency.

Superior property

- Highly resistant to mechanical strength, high temperature strength and excellent thermal shock resistance. Excellent electrical insulation, dielectric strength and thermal shock resistance. The resistance element are isolated alowing excellent oxidation resistance as well as excellent chemical resistance.

Range of temperature

- 1200~1400 °C

Material

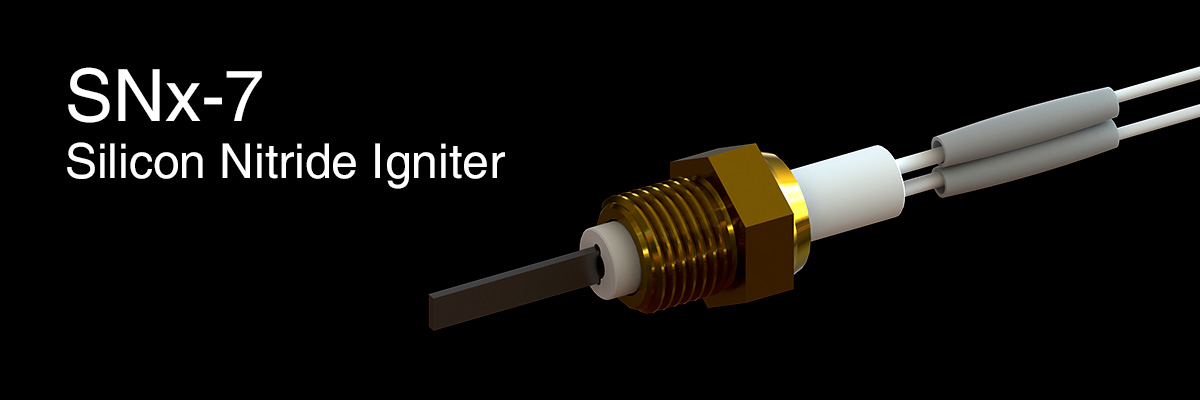

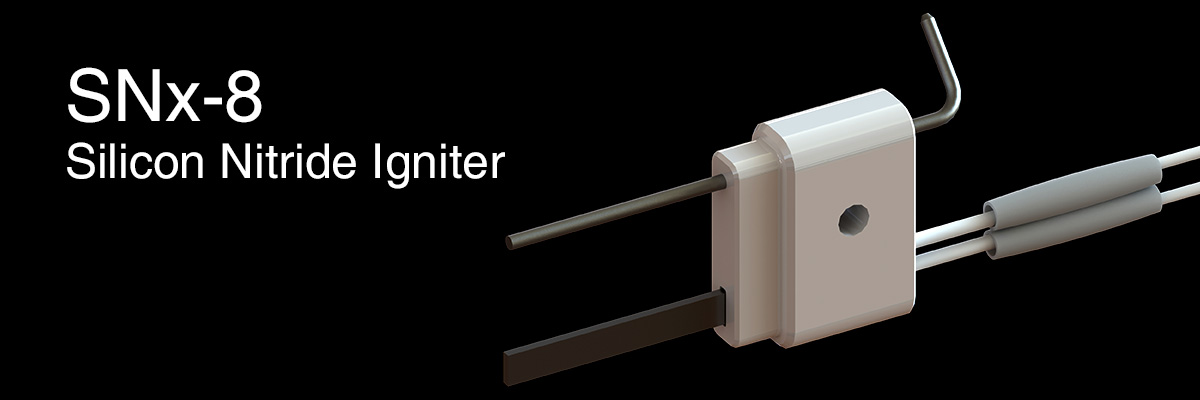

- Heating element: Sillicon Nitride (Si3N4)